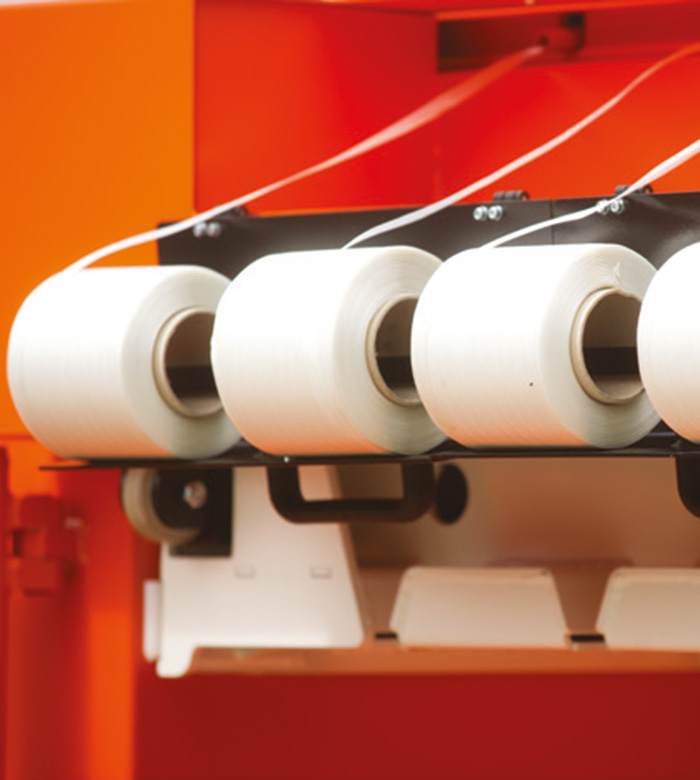

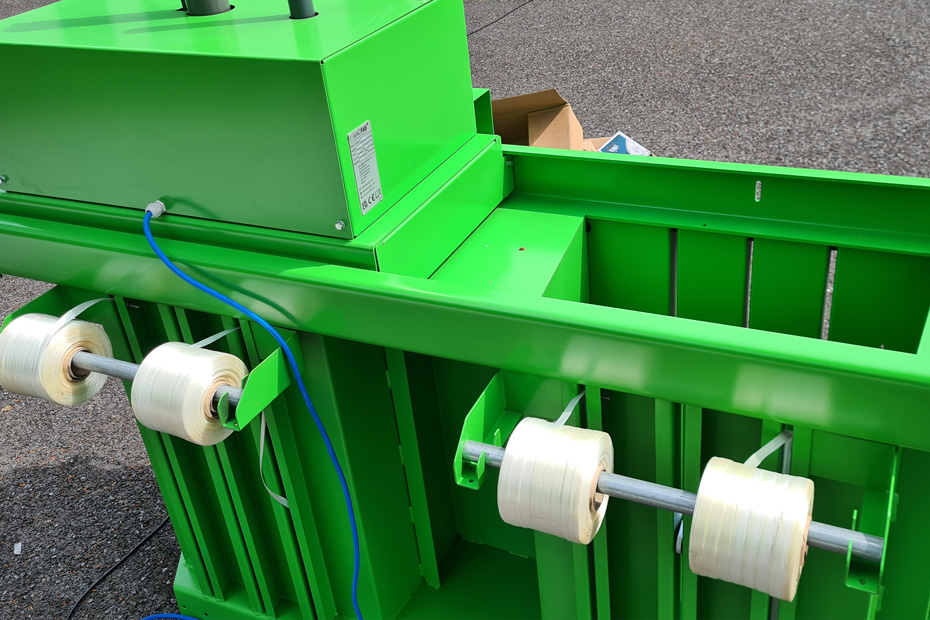

In the modern waste management and recycling industry, efficiency and reliability are crucial to ensuring cost-effective and sustainable operations. One of the most important steps in recycling is the compression of waste materials into compact bales for easier transportation and storage. Recycling compressors, also known as baling machines, play a vital role in this process by compacting materials such as paper, plastic, and metal into dense bales. To secure these bales effectively, high-performance strapping solutions are required.

Among the various strapping options available, bonded (textile) strapping has emerged as a superior choice due to its durability, safety, and cost-effectiveness. This article explores how bonded textile strapping enhances efficiency in recycling compressors by improving security, reducing operational costs, and ensuring environmental sustainability.

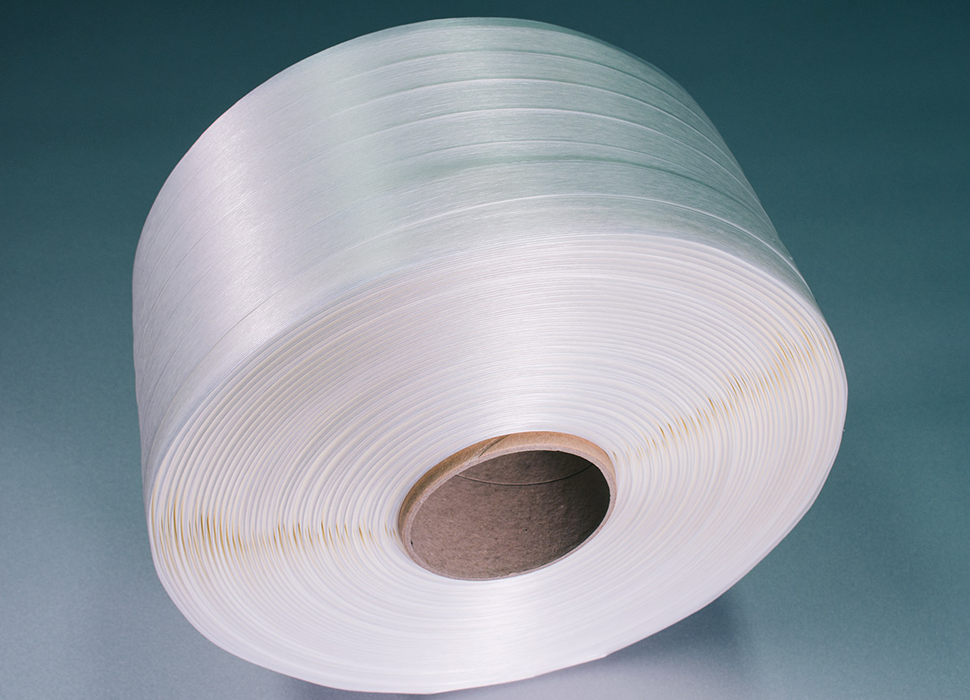

1. Understanding Bonded (Textile) Strapping

Bonded textile strapping is made from high-tenacity polyester fibers that are bonded together with adhesive. This type of strapping is designed to provide exceptional strength, flexibility, and resistance to external factors such as moisture and UV exposure. Unlike traditional steel or plastic strapping, bonded textile strapping offers a safer and more user-friendly alternative while maintaining high tension and load stability.

Key characteristics of bonded textile strapping include:

- High tensile strength: It can withstand heavy loads and high tension without breaking.

- Flexibility: It conforms to the shape of the compressed materials, ensuring a secure hold.

- Shock absorption: It resists sudden impacts and vibrations, reducing the risk of bale breakage.

- Corrosion resistance: Unlike steel strapping, it does not rust, making it ideal for outdoor storage.

2. Enhancing Bale Security and Stability

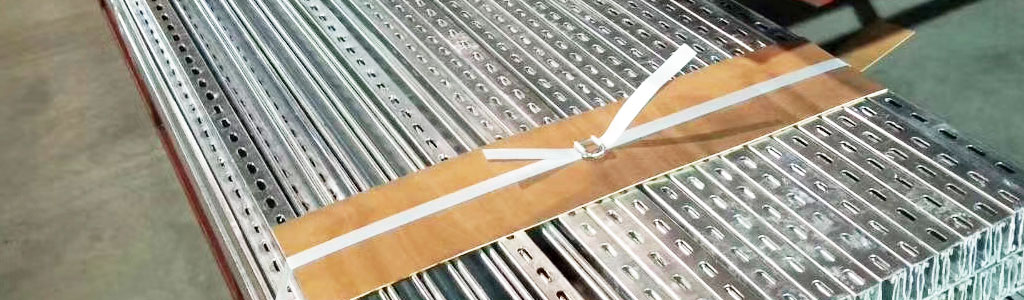

One of the primary advantages of using bonded textile strapping in recycling compressors is its ability to provide superior bale security. When materials are compressed, they must be strapped tightly to maintain their compact form during handling and transportation.

Bonded textile strapping ensures:

- Strong and consistent tension: It maintains uniform pressure across the entire bale, preventing shifting or loosening.

- Minimal elongation: Unlike some plastic strapping that may stretch over time, bonded strapping retains its original tension.

- Reliable knotting and buckling: It can be secured using wire buckles or friction-based seals, ensuring a firm grip that does not slip.

These features help prevent accidents and reduce product loss, which is essential for recycling facilities that handle large volumes of waste materials daily.

3. Improving Operational Efficiency and Cost-Effectiveness

Switching to bonded textile strapping in recycling compressors can significantly improve operational efficiency and reduce costs.

a) Easy Handling and Application

Bonded textile strapping is lightweight and easy to handle, making it simpler for workers to apply compared to steel strapping. It can be tensioned manually using simple tools, eliminating the need for expensive pneumatic or battery-powered tensioners. This reduces labor time and effort, leading to increased productivity in recycling operations.

b) Reduced Equipment Wear and Tear

Steel strapping often causes wear and tear on baling machines due to its rigid and abrasive nature. Bonded textile strapping, on the other hand, is soft and does not damage machine components. This extends the lifespan of recycling compressors and reduces maintenance costs.

c) Lower Transportation Costs

Since bonded textile strapping is strong yet lightweight, it does not add excessive weight to the compressed bales. This can lower transportation costs, especially for recycling companies that ship large quantities of waste materials over long distances.

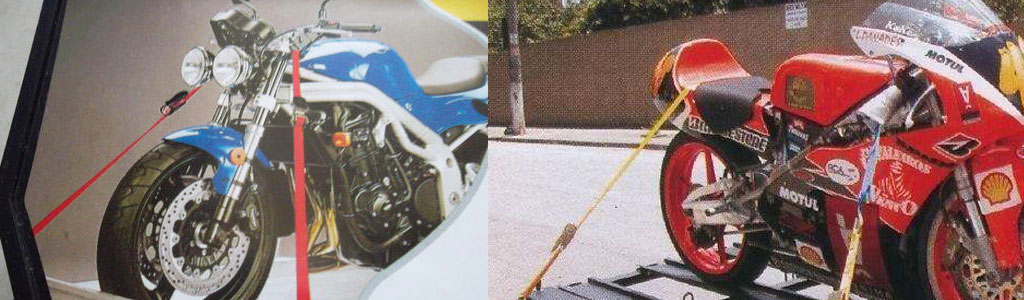

4. Enhancing Safety in Recycling Operations

Safety is a major concern in recycling facilities, where workers frequently handle heavy bales and strapping materials. Bonded textile strapping offers significant safety benefits over traditional steel strapping:

- No sharp edges: Unlike steel strapping, which can cause cuts and injuries, bonded strapping is soft and safe to handle.

- Elastic recovery: It absorbs sudden shocks and does not snap unexpectedly, reducing the risk of accidents.

- Non-corrosive: It does not rust or degrade, ensuring long-term reliability in various environmental conditions.

These advantages contribute to a safer working environment, reducing workplace injuries and improving overall efficiency.

5. Environmental Benefits of Bonded Textile Strapping

Sustainability is a key priority in the recycling industry, and bonded textile strapping aligns well with eco-friendly practices.

- Recyclability: Many bonded strapping materials are recyclable, reducing overall waste generation.

- Lower carbon footprint: The production and transportation of bonded textile strapping require less energy compared to steel strapping, contributing to lower greenhouse gas emissions.

- No chemical pollution: Unlike some plastic strapping that releases harmful chemicals when disposed of, bonded textile strapping is a safer alternative.

By adopting bonded textile strapping, recycling companies can enhance their sustainability efforts while maintaining high operational efficiency.

6. Conclusion

Bonded textile strapping is a game-changer for recycling compressors, offering unmatched benefits in terms of security, efficiency, safety, and sustainability. Its high tensile strength, flexibility, and durability make it an ideal choice for securing compressed bales in recycling facilities. Moreover, its cost-effectiveness and ease of use contribute to streamlined operations and reduced expenses.

As the recycling industry continues to evolve, adopting advanced strapping solutions like bonded textile strapping will be essential for improving productivity and achieving long-term sustainability. By making this simple yet effective switch, recycling facilities can enhance their performance while minimizing environmental impact.