When it comes to securing heavy-duty shipments, choosing the right strapping material is critical. Shipments that involve industrial equipment, construction materials, or other large and heavy items require a durable, reliable, and safe strapping solution. Woven polyester banding has gained popularity as an effective alternative to traditional steel and plastic strapping due to its strength, flexibility, and ease of use.

This article explores the top reasons why woven polyester banding is the best choice for heavy-duty shipments, highlighting its advantages in durability, safety, cost-effectiveness, and sustainability.

1. Exceptional Strength and Durability

One of the biggest reasons for using woven polyester banding in heavy-duty shipments is its high tensile strength. Unlike standard plastic straps, which can snap under pressure, or steel straps, which may bend or break, woven polyester banding is designed to withstand extreme loads.

**High Load Capacity**

- Woven polyester banding can secure loads up to several tons, making it suitable for palletized goods, construction materials, and machinery.

- Its high tensile strength is comparable to steel strapping, but without the drawbacks of rust or sharp edges.

**Resistance to Wear and Tear**

- The woven structure provides reinforced strength, preventing the strap from breaking under tension.

- Unlike steel, which can weaken due to corrosion, woven polyester banding is resistant to moisture, UV exposure, and harsh weather conditions.

- This makes it ideal for both indoor and outdoor shipments, including maritime and long-distance freight transportation.

2. Enhanced Load Stability

Proper load stability is essential for preventing damage to goods during transit. Woven polyester banding provides superior shock absorption and load retention, making it a preferred choice for securing heavy shipments.

**Shock Absorption**

- During transportation, heavy shipments experience vibrations, sudden movements, and impact.

- Unlike steel strapping, which is rigid and can cause damage, woven polyester banding absorbs shocks and maintains tension, preventing cargo from shifting.

- This is especially beneficial for fragile or high-value items, ensuring they arrive safely.

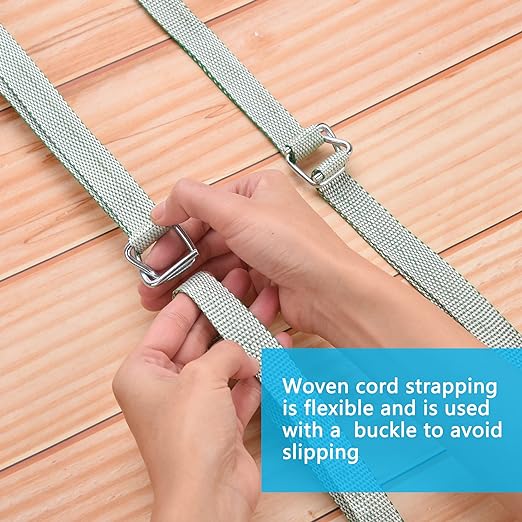

**Non-Slip Surface**

- The woven texture of the banding provides a strong grip, reducing the risk of straps slipping or loosening.

- It maintains tightness even when exposed to temperature changes or humidity, ensuring long-term load stability.

3. Superior Safety Compared to Steel Strapping

Safety is a major concern when handling heavy shipments. Steel strapping, while strong, presents significant risks:

- Sharp edges can cause serious injuries to workers.

- Recoil danger when cutting steel straps can lead to accidents.

- Steel is heavy and difficult to handle, increasing strain on workers.

**Why Woven Polyester Banding is Safer:**

✅ No sharp edges – reduces the risk of cuts and injuries.

✅ No dangerous recoil – remains flexible when cut.

✅ Lightweight and easy to handle, reducing worker fatigue.

These factors make woven polyester banding a safer alternative for industrial applications, ensuring a secure work environment while maintaining high performance.

4. Cost-Effectiveness and Efficiency

Businesses looking for a cost-effective solution for securing heavy-duty shipments will find woven polyester banding to be an excellent investment.

**Lower Material and Handling Costs**

- Woven polyester banding is more affordable than steel strapping in terms of both material costs and handling expenses.

- It does not require specialized sealing tools, reducing equipment costs.

- Lightweight nature reduces shipping expenses compared to heavier alternatives.

**Reusability for Long-Term Savings**

- Unlike traditional plastic straps that are single-use, woven polyester banding can often be reused, reducing waste and lowering long-term packaging costs.

- This makes it an environmentally friendly option while maximizing cost efficiency for businesses handling repeated shipments.

5. Easy Application and Versatility

Woven polyester banding is designed for convenience, making it easy to apply and secure shipments without specialized training.

**Simple and Quick Installation**

- Can be applied using manual tensioners, buckles, or battery-powered tools.

- Unlike steel strapping, which requires crimping and cutting tools, woven polyester banding can be tightened and secured with simple hand tools.

- This speeds up the packaging process and reduces labor time.

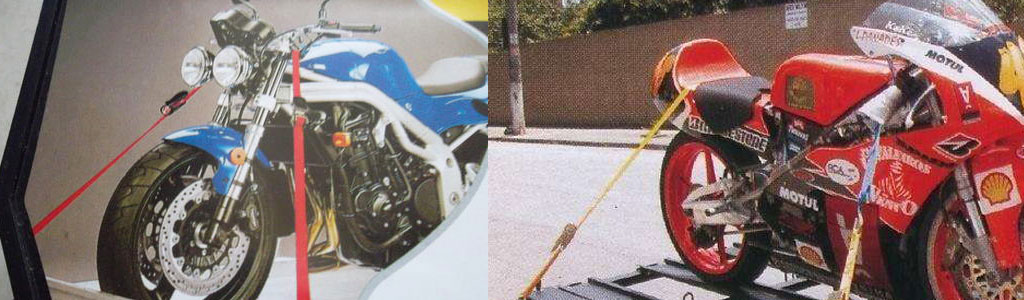

**Versatile for Various Industries**

- Suitable for a wide range of heavy-duty applications, including:

- Construction materials (bricks, timber, metal sheets)

- Automotive industry (securing vehicle parts and machinery)

- Manufacturing and warehousing (palletized loads)

- Shipping and freight transport (securing oversized cargo)

Its adaptability across industries makes it a go-to solution for businesses needing a strong and reliable strapping system.

6. Eco-Friendly Alternative to Steel and Plastic Strapping

Sustainability is becoming a top priority for businesses worldwide. Woven polyester banding is an eco-friendly alternative to traditional packaging materials.

**Recyclable and Sustainable**

- Unlike plastic strapping, which contributes to landfill waste, woven polyester banding can be recycled and reused, reducing environmental impact.

- Steel strapping requires significant energy to produce and transport, making it less eco-friendly than polyester-based options.

**Lower Carbon Footprint**

- Being lightweight, woven polyester banding reduces fuel consumption in transportation, lowering carbon emissions.

- Businesses looking to improve their sustainability efforts can benefit from switching to this eco-conscious solution.

Conclusion

For businesses handling heavy-duty shipments, choosing the right strapping solution is crucial for safety, cost-efficiency, and reliability. Woven polyester banding outperforms steel and plastic alternatives by offering:

✅ Exceptional strength and durability for securing heavy loads

✅ Shock absorption and non-slip grip for enhanced load stability

✅ Superior safety features, reducing worker injuries

✅ Lower material and handling costs, making it cost-effective

✅ Quick and easy application, saving time in packaging

✅ Environmentally friendly advantages, supporting sustainability

Whether shipping construction materials, industrial equipment, or large cargo, woven polyester banding is the ideal solution for ensuring secure, efficient, and safe transport.

By making the switch to woven polyester banding, businesses can improve shipping reliability, reduce costs, and enhance overall safety, making it the best strapping choice for heavy-duty applications.