In the world of waste management and recycling, efficiency and reliability are crucial. One of the most essential tools in ensuring that materials remain secure, compact, and transportable during handling, storage, and shipping is bale press strapping. Whether you're working with cardboard, plastic, paper, or metals, the proper strapping solution ensures that everything stays in place, reducing waste, enhancing productivity, and minimizing risk.

This guide will take an in-depth look at bale press strapping, including what it is, its key uses, and the numerous benefits it offers, particularly in waste management and recycling.

What is Bale Press Strapping?

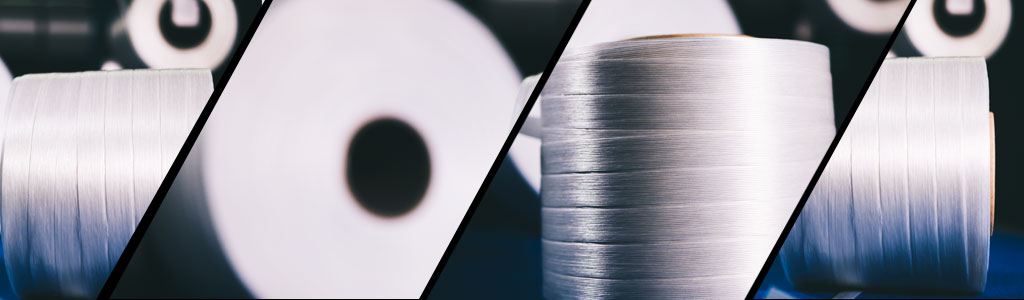

Bale press strapping, also known as baler strapping, refers to the use of strong, durable straps to secure and bundle materials into tight, stable bales. Typically made from materials like polyester, polypropylene, or steel, these strapping materials are designed to withstand the intense pressure exerted during the baling process and ensure the integrity of the compressed material during handling and transport.

In industries like recycling, agriculture, and manufacturing, bale press strapping plays a vital role in making bulk materials more manageable, transportable, and safe. It is commonly used in baling machines that compact waste materials, recyclables, or other goods into manageable units, ready for transportation or storage.

Key Uses of Bale Press Strapping

1. **Recycling and Waste Management**

One of the most common applications for bale press strapping is in the recycling and waste management industries. Materials like cardboard, plastic, and paper are typically compressed into bales to make them easier to transport to processing facilities. Bale press strapping ensures these materials stay tightly bound together, reducing the risk of spills and contamination during transit.

By securely binding these materials, bale press strapping minimizes the potential for materials to shift or fall apart, making the recycling process more efficient. It also helps in optimizing storage space at recycling centers, as compressed bales take up less room compared to loose, uncompressed materials.

2. **Agriculture**

In the agricultural sector, bale press strapping is often used to secure bales of hay, straw, or other agricultural products. Strapping these materials tightly prevents them from breaking apart, ensuring that farmers can transport and store them more easily. In some cases, the bales may be stored for extended periods before use, so the durability of the strapping is critical in maintaining the quality of the materials inside.

Bale press strapping also reduces the risk of material loss due to external factors such as moisture or wind, which could lead to waste and additional costs for farmers.

3. **Manufacturing**

The manufacturing industry also benefits from bale press strapping, especially when bundling metal scraps, textiles, or other bulk materials. The use of strapping makes these items more stable and easier to move. By keeping everything securely packed, it reduces the risk of spillage or damage during the transportation of heavy materials across factories or between production sites.

4. **Cardboard and Paper Recycling**

As one of the most recyclable materials, cardboard and paper are commonly compressed into bales for transportation and recycling. Baler strapping is essential in keeping these materials tightly bound so that they can be efficiently transported to recycling plants. Without proper strapping, these bales could lose their integrity, potentially causing damage to other materials or creating inefficiencies in the recycling process.

Benefits of Bale Press Strapping

1. **Enhanced Load Security**

The primary benefit of bale press strapping is its ability to securely hold compressed materials together. Whether dealing with paper, plastic, metals, or agricultural products, the strapping ensures that the contents remain in place, preventing any shifting or movement that could lead to spills or accidents.

In recycling, for example, this level of security ensures that the bales are handled safely during transit and do not break apart, reducing contamination risks and the potential for lost materials.

2. **Increased Efficiency in Handling**

Bale press strapping significantly improves material handling. Compressed bales bound with strong strapping are easier to move, stack, and store. Instead of dealing with loose piles of material, which are cumbersome and time-consuming to handle, employees can work more quickly and safely when dealing with neatly packed bales.

Forklifts and other material handling equipment can move strapping-bound bales with greater ease, saving both time and energy, while reducing the risk of accidents or workplace injuries.

3. **Cost-Effective Solution**

Bale press strapping is a cost-effective solution for companies looking to optimize their waste management or material handling processes. Compared to other packaging or binding options, such as wire or steel strapping, baler strapping materials—particularly polyester and polypropylene—are often more affordable while still offering excellent strength and durability.

Additionally, automated strapping machines can speed up the bundling process, reducing labor costs and allowing for more efficient operations overall.

4. **Sustainability and Environmental Impact**

As industries face growing pressure to reduce their environmental impact, bale press strapping offers a sustainable solution for waste management. Many types of baler strapping are made from recyclable materials like polyester, which can be reused and repurposed after use. By using recyclable strapping, companies can contribute to a circular economy, reducing waste and supporting more sustainable practices in packaging and logistics.

Furthermore, properly strapped bales are easier to handle and transport, which can reduce the carbon footprint associated with handling and shipping materials.

5. **Improved Safety**

Safety is a critical concern in any industry that deals with heavy materials, and bale press strapping plays a crucial role in minimizing risks. By securely binding materials together, strapping prevents bales from falling apart or shifting unexpectedly. This not only helps protect the materials themselves but also reduces the likelihood of accidents or injuries to employees who handle the bales.

Well-strapped bales are less likely to tip over or spill during transport, creating a safer working environment for warehouse and factory employees.

6. **Versatility in Applications**

Bale press strapping is highly versatile and can be used across a wide range of industries. Whether for recycling, agriculture, manufacturing, or logistics, strapping can be applied to a variety of materials, from lightweight paper products to heavy metal scraps. This versatility makes it an indispensable tool in numerous sectors, simplifying the process of material handling, storage, and transportation.

Conclusion

Bale press strapping is an essential component in the efficient and secure handling of materials across various industries. Whether you're dealing with recyclable materials, agricultural products, or manufacturing waste, the right strapping ensures that your goods remain compact, secure, and ready for transport or storage. The numerous benefits—from enhanced load security to cost savings and improved safety—make bale press strapping an indispensable tool for businesses seeking to optimize their operations, reduce waste, and improve overall productivity.

With its wide range of applications, cost-effectiveness, and positive environmental impact, bale press strapping is truly the backbone of efficient waste management and material handling systems.