In modern logistics and transportation, ensuring the safe and secure delivery of goods is a top priority. From manufacturers shipping heavy machinery across continents to local businesses delivering stacked pallets of products, the safe movement of cargo is essential not only for protecting goods but also for safeguarding lives and equipment. Among the most effective tools in achieving this goal is the heavy-duty lashing strap.

Designed to secure loads under the most demanding conditions, heavy-duty lashing straps are a practical and essential component of cargo safety systems. They help prevent load shifts, reduce the risk of accidents, and ensure compliance with industry safety standards. This article explores how heavy-duty lashing straps contribute to transportation safety, examining their benefits, applications, and best practices for use.

Understanding Heavy-Duty Lashing Straps

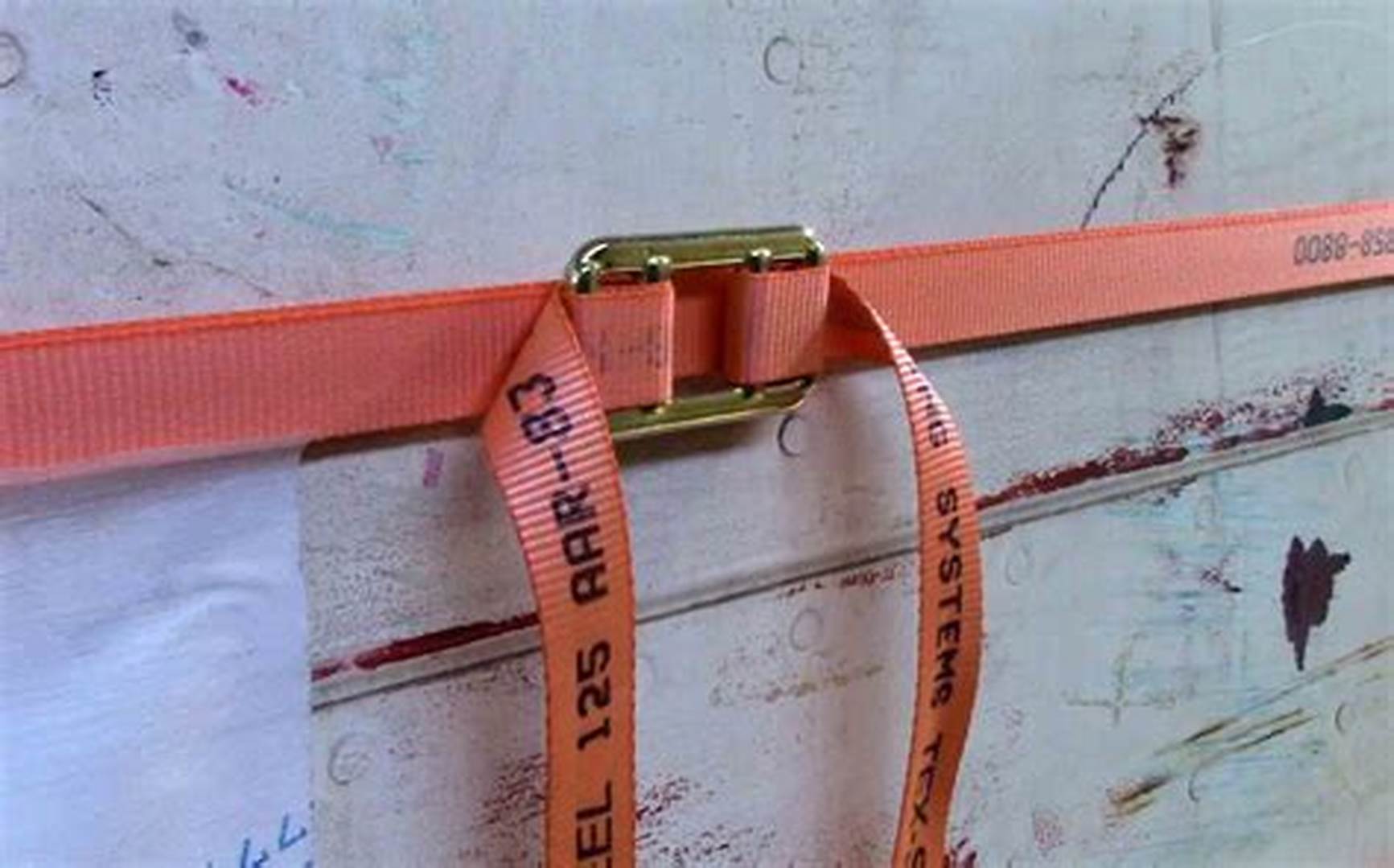

A heavy-duty lashing strap is a tensioned tie-down device used to secure cargo during transit. It consists of a durable webbing strap, usually made of high-tensile polyester, and a tensioning mechanism such as a ratchet or cam buckle. These straps can be used to restrain goods on trucks, in containers, on railcars, or even aboard ships and planes.

The webbing material provides the flexibility needed to wrap around various cargo shapes while maintaining high breaking strength. Polyester is commonly used due to its resistance to UV rays, moisture, chemicals, and abrasion. These qualities ensure reliable performance even in the harshest transport environments.

Key Role in Transportation Safety

The use of heavy-duty lashing straps is central to cargo security and transportation safety for several reasons.

-Prevention of Load Shifting

One of the primary functions of a lashing strap is to prevent cargo from shifting during movement. A sudden turn, quick stop, or bumpy road can create enough force to dislodge unsecured loads. This shifting can damage products, destabilize the vehicle, or lead to rollovers. Lashing straps help eliminate such movement by applying constant pressure, keeping everything locked tightly in place.

-Protection for Drivers and Road Users

Unsecured cargo is not only dangerous to the driver but also to other road users. Falling goods can cause accidents, road blockages, or serious injury. Properly secured loads reduce the risk of such hazards, contributing to safer roads and fewer incidents.

-Enhanced Operational Efficiency

Secure loads lead to smoother transport operations. When cargo is properly strapped, drivers can operate with confidence, and loading and unloading processes become faster and more efficient. This reduces delays, damages, and associated costs.

-Industries That Rely on Heavy-Duty Lashing Straps

The application of lashing straps spans various industries. In each, the safety and reliability they provide make them indispensable.

-Freight and Logistics

Trucking and shipping companies use lashing straps to secure loads such as containers, pallets, and machinery. These straps are suitable for over-the-road transport, sea freight, and rail.

-Construction and Heavy Equipment

Construction companies transport large, often oddly shaped items such as beams, concrete panels, and heavy tools. Lashing straps provide the flexibility to hold these items firmly without causing surface damage.

-Agriculture

Farmers and agricultural suppliers rely on heavy-duty straps to tie down hay bales, seed bags, and equipment. The strength and weather resistance of polyester webbing make it ideal for outdoor and off-road use.

-Warehousing and Material Handling

Straps are used in warehouses to secure goods on racks, stabilize items on forklifts, and bundle materials for shipment or storage.

Choosing the Right Lashing Strap for Safety

Not all lashing straps are created equal. Selecting the correct strap is essential to ensuring safety and performance.

-Working Load Limit (WLL)

The WLL is the maximum load a strap can handle during use. It is critical to choose a strap with a WLL that matches or exceeds the weight of the cargo. Overloading a strap can lead to failure and serious safety risks.

-Strap Length and Width

Straps come in various lengths and widths to accommodate different cargo sizes. Wider straps generally offer better load distribution, reducing the risk of damaging delicate items.

-Tensioning Mechanism

Ratchet straps provide high tension and are ideal for very heavy loads, while cam buckle straps are easier to operate and best for lighter goods. Choosing the right mechanism ensures the balance between security and ease of use.

-Attachment Ends

Different hooks and fittings—such as flat hooks, wire hooks, or E-track connectors—are used to match anchor points on trailers and containers. Using compatible end fittings improves the integrity of the securing system.

Best Practices for Safe Use

Even the best lashing straps must be used correctly to ensure maximum safety. Here are some guidelines to follow.

-Inspect Straps Before Each Use

Always check for signs of wear, fraying, or damage. Even a small cut or abrasion can compromise the strength of the strap. Replace any strap that does not pass visual inspection.

-Apply Even Tension

Straps should be tightened evenly to prevent imbalance or shifting. Over-tightening can damage the cargo, while under-tightening can lead to movement during transit.

-Avoid Twisting the Strap

A twisted strap reduces load capacity and creates uneven tension. Make sure the strap lies flat against the cargo for maximum surface contact and stability.

-Use Appropriate Anchor Points

Straps must be attached to solid, fixed anchor points capable of handling the force. Improvised connections can fail under tension, creating hazards.

-Store Straps Properly

After use, clean and dry your straps and store them in a cool, dry place away from sunlight. Proper storage extends their lifespan and maintains their performance.

-Training and Awareness

One often overlooked aspect of using heavy-duty lashing straps is proper training. Drivers, loaders, and warehouse staff should all understand how to use the straps effectively. Training programs should include load assessments, proper strap selection, safe tightening techniques, and inspection routines.

Raising awareness of cargo securing not only reduces damage and injuries but also builds a culture of safety within the organization. Regular refreshers and updates on best practices help keep safety front and center in daily operations.

The Future of Safe Transport

As the transportation industry continues to evolve, so do the tools and methods used to ensure safety. Innovations in strap materials, smart tensioning systems, and real-time load monitoring are on the horizon. However, the core principles of load securing remain the same, and heavy-duty lashing straps will continue to play a vital role in any secure cargo operation.

Conclusion

Heavy-duty lashing straps are more than just tools; they are an essential part of transportation safety. Their ability to secure loads in a wide variety of environments and conditions makes them indispensable for businesses that rely on the safe, efficient movement of goods.

By selecting the right straps, following best practices, and prioritizing safety training, companies can greatly reduce the risks associated with cargo transport. In doing so, they not only protect their goods and vehicles but also contribute to safer roads, ports, and workplaces around the world.

In the pursuit of safety, no detail is too small—and heavy-duty lashing straps are a small detail that makes a big difference.