Introduction

In the modern world of industrial operations and logistics, the safe and efficient transportation of goods is critical. Whether transporting raw materials, finished products, or heavy machinery, ensuring cargo security is a top priority. Lashing straps have become an essential tool in securing loads during transportation, providing a reliable and cost-effective way to prevent damage and accidents.

Lashing straps are widely used across industries such as manufacturing, construction, shipping, and warehousing, playing a crucial role in maintaining supply chain efficiency. This article explores the role of lashing straps in industrial and logistics sectors, detailing their importance, benefits, and applications in various fields.

1. Understanding Lashing Straps

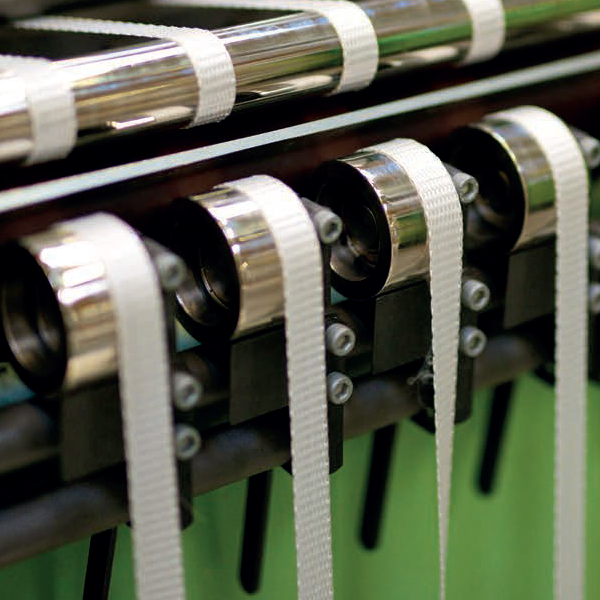

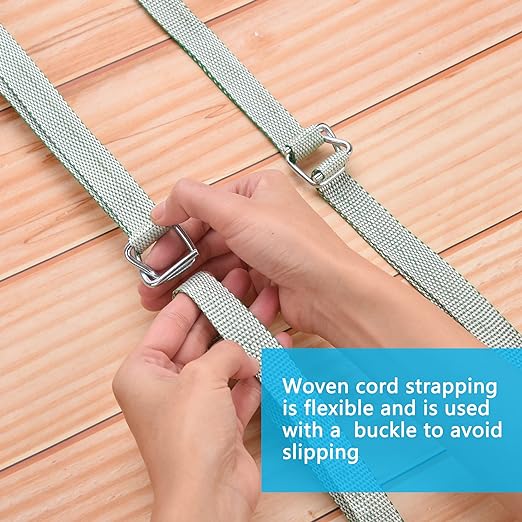

Lashing strap, also known as woven strap, is a high-strength webbing belt used to secure cargo during transportation or storage. Made from polyester, nylon, or polypropylene, these straps offer excellent durability, resistance to harsh weather conditions, and flexibility for different load-securing needs.

2. Importance of Lashing Straps in the Industrial and Logistics Sectors

2.1 Ensuring Safe Transportation of Goods

One of the primary roles of lashing straps is securing cargo to prevent movement during transit. Whether transported by truck, ship, train, or airplane, goods are exposed to vibrations, sudden stops, and rough handling. Without proper securing, cargo can shift, leading to:

- Damage to products

- Increased safety risks for workers and drivers

- Regulatory fines for improper load securing

By using high-quality lashing straps, companies minimize cargo movement, ensuring that products reach their destination in perfect condition.

2.2 Compliance with Safety Regulations

Industrial and logistics companies must adhere to strict safety regulations regarding cargo securing. Organizations such as the Department of Transportation (DOT), European Union Road Transport Regulations, and International Maritime Organization (IMO) have specific guidelines for securing loads.

Lashing straps help businesses meet these standards by:

- Providing the required tensile strength for load securing

- Ensuring cargo stability during transport

- Preventing legal penalties due to improper load securing

Using lashing straps not only enhances safety but also ensures compliance with national and international transportation laws.

2.3 Improving Efficiency in Cargo Handling

In logistics and industrial sectors, time is a crucial factor. Traditional load-securing methods, such as chains and ropes, can be time-consuming and require additional labor. Lashing straps provide a quick and efficient alternative.

Key benefits include:

- Easy fastening and release mechanisms

- Lightweight design for quick handling

- Adjustability for different cargo sizes and shapes

By streamlining the cargo securing process, businesses can improve productivity and reduce labor costs.

2.4 Protecting High-Value Equipment and Machinery

Industries such as construction, manufacturing, and aerospace often transport heavy machinery, industrial parts, and sensitive equipment. Improper securing can cause costly damage or even lead to project delays.

Lashing straps are designed to:

- Secure heavy loads without damaging surfaces

- Provide shock absorption during transit

- Prevent machinery from shifting and falling

Using reinforced lashing straps with high load capacity ensures the safe transportation of expensive equipment, minimizing financial risks.

3. Applications of Lashing Straps in Industrial and Logistics Sectors

3.1 Trucking and Road Transport

Trucking companies rely heavily on lashing straps to secure:

- Palletized goods

- Construction materials

- Vehicles and machinery

Why lashing straps are preferred:

✅ They offer strong tensioning capabilities

✅ They are lighter than chains (reducing overall vehicle weight)

✅ They prevent cargo from shifting without causing surface damage

3.2 Shipping and Maritime Industry

In ocean freight, cargo containers, machinery, and bulk goods require strong securing. Lashing straps are used to:

- Fasten goods inside shipping containers

- Secure cargo on open-deck vessels

- Prevent movement caused by waves and weather conditions

Heavy-duty polyester lashing straps are ideal for maritime transport as they are resistant to saltwater corrosion and UV exposure.

3.3 Aviation and Air Freight

Cargo transported by air must be securely fastened to withstand turbulence and pressure changes. Lashing straps play a key role in:

- Securing cargo inside aircraft cargo holds

- Holding palletized goods in place during flights

- Ensuring compliance with international air cargo regulations

Aviation logistics companies prefer lashing straps because they are lightweight yet extremely strong, helping to optimize fuel efficiency.

3.4 Warehouse and Storage Operations

Warehouses use lashing straps to:

- Secure stacked goods on shelves

- Bundle products together for easier handling

- Prevent shifting of inventory in storage racks

Using lashing straps in warehouses reduces product damage and enhances workplace safety by keeping items securely in place.

3.5 Construction and Heavy Equipment Transport

In the construction sector, lashing straps are used to secure scaffolding, steel beams, concrete blocks, and heavy machinery during transportation.

Advantages for the construction industry:

✅ Provides strong securing for heavy loads

✅ Prevents damage to building materials

✅ Helps transport oversized equipment safely

Using industrial-strength lashing straps ensures that materials reach construction sites without damage or delays.

4. Advantages of Using Lashing Straps in Industrial and Logistics Sectors

4.1 Cost-Effective Solution

Compared to metal chains or wire ropes, lashing straps are:

✔ More affordable

✔ Reusable multiple times

✔ Require minimal maintenance

4.2 Lightweight and Easy to Handle

Lashing straps are much lighter than traditional load-securing methods, making them easier to transport and store.

4.3 Safe for Delicate Cargo

Unlike chains that can cause scratches and dents, lashing straps provide a softer yet secure hold, making them perfect for fragile or sensitive items.

4.4 Versatile and Adjustable

Lashing straps can be used for various load sizes and shapes, ensuring flexibility in different logistics operations.

Conclusion

Lashing straps are an indispensable tool in the industrial and logistics sectors, providing a safe, reliable, and cost-effective solution for securing cargo. From trucking and maritime shipping to aviation and warehouse storage, these straps ensure that goods remain stable, undamaged, and compliant with regulations.

By investing in high-quality lashing straps, businesses can enhance efficiency, reduce losses, and improve overall transport safety. Whether securing heavy machinery, fragile goods, or bulk shipments, lashing straps play a vital role in maintaining the smooth flow of goods across industries.

For any company involved in logistics and industrial transportation, choosing the right lashing straps is key to ensuring cargo security and operational success.