In the ever-evolving world of industrial packaging and logistics, choosing the right materials to secure goods for transport is critical. One material that has gained considerable attention in recent years due to its remarkable durability, strength, and versatility is **woven strapping**. Made primarily from polyester fibers, woven strapping combines the benefits of both flexibility and resilience, making it an excellent choice for a wide range of industrial applications. This article delves into the numerous benefits of woven strapping, particularly in industrial settings, and explores why it is becoming a preferred solution for securing goods during transport, storage, and handling.

### What is Woven Strapping?

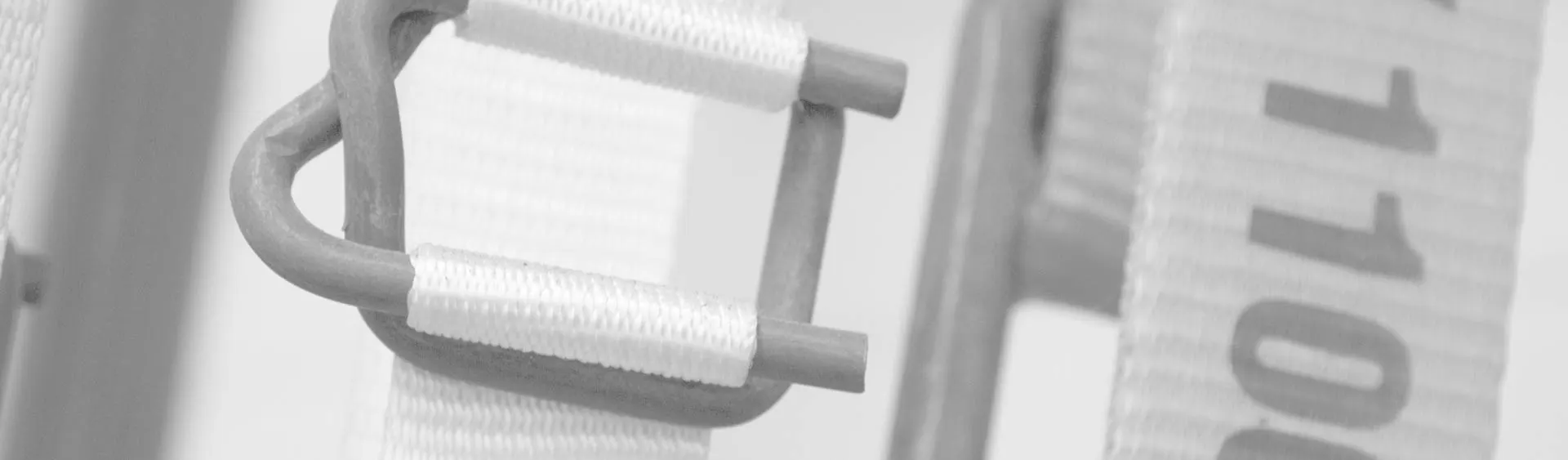

Woven strapping is a type of packaging material made from synthetic fibers, typically polyester, that are woven together to create a flexible yet strong band. Unlike traditional steel or polypropylene straps, woven strapping is designed to withstand a wide range of stresses while remaining lightweight and easy to handle. Its design incorporates a series of tightly interlaced fibers, which provide superior tensile strength and flexibility, allowing it to secure heavy loads effectively.

While it is often compared to steel strapping due to its strength, woven strapping is much lighter, resistant to environmental factors like UV rays and moisture, and does not suffer from the same rusting or corrosion issues. This makes woven strapping an ideal choice for many industries, including manufacturing, automotive, construction, and logistics.

### Key Benefits of Woven Strapping for Industrial Applications

Woven strapping offers several advantages that make it a superior choice for industrial packaging. Let’s take a deeper look at the key benefits:

#### 1. **High Strength and Load-Bearing Capacity**

One of the most significant advantages of woven strapping is its **high tensile strength**, which makes it capable of securing heavy loads without breaking. Polyester fibers are engineered to withstand significant tension, meaning that woven strapping can support large, heavy, and bulky items often encountered in industrial settings.

Whether you're transporting construction materials, heavy machinery, or large automotive components, woven strapping provides the necessary strength to hold these items securely in place during transit. In addition to its strength, woven strapping can absorb impacts and vibrations that might occur during transport, ensuring that the load remains stable and undamaged.

#### 2. **Durability and Weather Resistance**

Industrial applications often involve outdoor or harsh environment shipping where the material is exposed to UV rays, moisture, extreme temperatures, and even abrasive surfaces. Unlike steel strapping, which can rust and deteriorate over time when exposed to the elements, woven strapping is resistant to these weather-related issues. The polyester fibers used in woven strapping do not degrade under UV exposure, nor do they corrode when in contact with moisture.

This resistance to the elements makes woven strapping ideal for use in industries such as agriculture, construction, and manufacturing, where goods may be stored outdoors or transported in various weather conditions. It maintains its strength and integrity regardless of temperature fluctuations, ensuring that industrial goods remain securely fastened and protected.

#### 3. **Impact and Abrasion Resistance**

Woven strapping is highly resistant to **abrasion** and **impacts**, two common risks associated with industrial handling and transportation. In many industrial applications, cargo is often exposed to rough handling, friction, and contact with abrasive surfaces. Whether items are being moved across a warehouse floor or transported in heavy machinery, woven strapping holds up exceptionally well under these conditions.

The design of woven strapping, which interlaces fibers tightly, allows it to absorb the impacts and resist wear and tear. This ensures that the strapping will not break or degrade during the loading and unloading process, even if the load is subject to harsh movements or shifting.

#### 4. **Flexibility and Adaptability**

While woven strapping is strong and durable, it also offers **flexibility**, which is a crucial feature for industrial applications. Many industrial goods, especially bulk materials or large machinery, have irregular shapes. Woven strapping can easily conform to the contours of these items, providing a snug fit without exerting excessive pressure that might damage the goods.

This flexibility also allows woven strapping to be used in applications where loads may shift or change shape during transport, such as when dealing with pallets of raw materials or machinery parts. Unlike rigid materials like steel, woven strapping can adapt to these changes, ensuring that the load remains securely fastened without damaging the cargo.

#### 5. **Cost-Effectiveness**

When compared to alternatives like steel strapping, woven strapping is often more cost-effective. Steel strapping, while incredibly strong, is not only more expensive but also prone to rusting and corrosion over time, leading to additional maintenance costs. Woven strapping, on the other hand, requires minimal maintenance, and its longevity means it doesn’t need to be replaced as frequently, reducing long-term costs.

Additionally, woven strapping is lightweight, which can lead to reduced transportation costs, especially when large volumes of strapping are required. Its easy handling and quick application also improve operational efficiency, reducing the time needed for packaging and securing shipments.

#### 6. **Safety Features**

Woven strapping is inherently safer than steel strapping for several reasons. First, the polyester fibers used in woven strapping do not have sharp edges, unlike steel, which can pose a risk of injury during handling. This makes woven strapping safer for workers in manufacturing facilities and warehouses.

Additionally, woven strapping is designed to absorb and distribute tension evenly across the load, reducing the chances of over-tightening or snapping during use. This helps prevent accidents caused by sudden release or failure of the strapping, further enhancing safety in industrial operations.

#### 7. **Environmental Friendliness**

With growing environmental concerns in industrial packaging, woven strapping presents a more sustainable alternative to steel or plastic strapping. Many woven straps are made from **recycled polyester** fibers, and the material itself can often be recycled after use. This reduces the environmental footprint compared to materials like plastic, which may not be biodegradable.

In addition, the lightweight nature of woven strapping reduces fuel consumption during transportation, helping to lower the carbon footprint of the shipping process. As industries continue to prioritize sustainability, woven strapping offers a practical and eco-friendly solution for packaging needs.

### Industrial Applications of Woven Strapping

Woven strapping is a versatile material that can be used across a wide range of industrial applications. Some of the most common include:

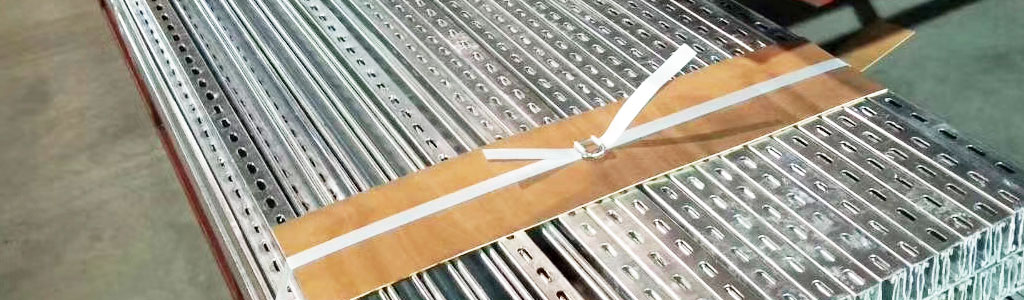

- **Palletized Goods**: Woven strapping is commonly used to secure palletized loads, whether they are boxes of consumer goods, construction materials, or heavy machinery. Its ability to secure a wide variety of load types makes it a go-to material in warehouse and shipping environments.

- **Construction Industry**: In the construction industry, woven strapping is used to secure large building materials, machinery, and tools. Its weather resistance and ability to withstand heavy loads make it ideal for this rugged environment.

- **Automotive Manufacturing**: The automotive industry frequently uses woven strapping to secure parts and components during shipment. Whether it's large automotive frames, engines, or delicate components, woven strapping ensures that each part arrives safely at its destination.

- **Agriculture**: Woven strapping is used in the agricultural industry to secure bales of hay, bundles of grain, and other bulk agricultural products. The strapping’s resistance to UV rays and moisture makes it ideal for outdoor storage and shipping of agricultural goods.

- **Paper and Textile Industry**: Woven strapping is also used in the paper and textile industries to bind rolls of paper or fabric. Its strength and flexibility make it well-suited for handling these materials, which can be heavy and difficult to secure.

### Conclusion

Woven strapping is quickly becoming a favorite in industrial applications due to its impressive combination of durability, strength, flexibility, and cost-effectiveness. Whether securing heavy machinery, bulk materials, or delicate goods, woven strapping provides a reliable and secure packaging solution that ensures goods reach their destination safely.

With its resistance to weather damage, UV exposure, and abrasions, woven strapping outperforms traditional materials like steel strapping in many applications. Furthermore, its ability to absorb impacts, distribute tension evenly, and its eco-friendly nature make it an ideal choice for industries focused on safety, efficiency, and sustainability.

In short, woven strapping offers unparalleled benefits for industrial applications, providing a robust and reliable solution that supports the needs of modern packaging, shipping, and logistics.